What is a Socket Weld Flange? Defining the High-Pressure Workhorse

In the world of industrial piping, socket weld flanges (SW flanges) are indispensable components, particularly when dealing with small-diameter, high-pressure lines.

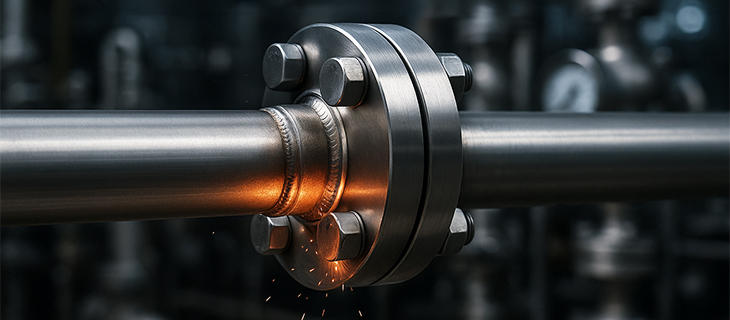

A socket weld flange is a type of flange designed with an internal recessed area, or “socket,” machined into the hub. This socket is precisely engineered to accept the outside diameter of a pipe. The design includes an internal shoulder, which acts as a guide or “positive stop,” ensuring the pipe is properly positioned and perpendicular to the flange face during fit-up.

Once the pipe is seated, the connection is permanently secured by applying a single fillet weld around the exterior of the hub.

SW flanges are specifically designed for applications where the pipe size is generally NPS 2 inches or smaller. They fill a critical gap between low-pressure slip-on flanges and complex, large-diameter butt-weld connections. While the highest pressure class, Class 2500, is typically excluded from socket weld specifications under ASME B16.5, these flanges are otherwise rated for high-pressure systems, including common industrial classes like Class 150 through Class 1500. They are also available in high-pressure fittings rated up to Class 9000.

Key Features and Advantages of Socket Weld Flanges

The popularity of the socket weld flange in demanding environments stems from a combination of strength, installation efficiency, and design integrity:

- High Strength and Leak Prevention: The socket design and the subsequent fillet weld create a robust, durable joint with superior leak resistance. They minimize gaps and potential points for fluid or gas leaks, making them ideal for containing hazardous or expensive fluids.

- Excellent Fatigue Life: The SW flange offers a fatigue strength that is 50% higher than a double-welded slip-on flange, making it suitable for systems subject to thermal cycling and vibration.

- Simplified Installation and Alignment: The socket instantly provides proper alignment and a snug fit, drastically reducing fitting time and errors. Crucially, the process of socket weld flange welding does not require beveling of the pipe ends, simplifying preparation compared to butt-welds.

- Space Efficiency: The compact design is an excellent choice for installations where space is constrained, such as in tight plant layouts or marine applications, where the long hub of a weld neck flange would be impractical.

- Internal Flow Characteristics: Compared to threaded fittings, socket welds are often cited for creating less turbulence due to a smoother interior bore, facilitating more efficient fluid flow and less pressure drop.

Critical Uses and Applications

The unique design parameters of the socket weld flange define its primary application niche:

- Steam and Condensate Lines: Their resistance to high pressure, high temperature, and thermal cycling makes them essential for robust connections in steam distribution systems, often handling steam pressures between 300 and 600 psi.

- Chemical and Petrochemical Processing: They are widely used for transporting hazardous, expensive, or toxic fluids in chemical plants, oil refineries, and gas pipelines, where leak prevention is paramount for safety and economics.

- Instrumentation and Hydraulic Systems: SW flanges provide vibration-resistant, secure connections for pressure gauges, flow meters, and control equipment in high-pressure hydraulic and compressed gas systems.

The Precision of Socket Weld Flange Welding: The Critical Gap

The success of a socket weld connection hinges entirely on the specialized procedure required for socket weld flange welding.

The most critical and non-negotiable step is maintaining the thermal expansion gap. After the pipe is inserted fully into the socket, it must be withdrawn approximately 1/16 inch (1.6 mm) away from the shoulder of the socket before the fillet weld is applied.

This gap serves a dual purpose: it prevents stress failure caused by the pipe expanding against the socket during the intense heat of welding, and it mitigates the buildup of locked-in tensile stresses once the weld cools. Failure to maintain this clearance can lead to cracking of the fillet weld.

Because of the joint geometry, traditional volumetric Non-Destructive Testing (NDT) like radiography is not practical for this fillet weld. Quality is instead verified through surface examination, such as Magnetic Particle Testing (MP) for carbon steel or Liquid Penetrant Testing (PT) for stainless steel parts.

Material Selection Guide for Socket Weld Flanges

Selecting the right material for your socket weld flange is critical, dictated by operating temperature, pressure, and the chemistry of the fluid being transported. Standard forged materials governed by ASTM specifications include:

| Material Type | ASTM Grade | Typical Application Niche |

| Carbon Steel | ASTM A105 | Standard choice for general industrial use, non-corrosive hydrocarbons, and moderate-temperature steam lines. |

| Stainless Steel | ASTM A182 F304/F304L | Offers general corrosion resistance for water and chemical services. F304L is the lower carbon grade preferred for welding. |

| Stainless Steel | ASTM A182 F316/F316L | Contains molybdenum, offering superior corrosion resistance to acids and chlorides (e.g., marine environments). |

| Alloy Steel | ASTM A182 F11, F22 | Known as Chrome-Moly, these grades provide high-temperature strength and creep resistance, vital for high-pressure, superheated steam in power generation. |

| Other High-Performance | Duplex, Nickel Alloys | Used when exceptional resistance to specific high-pressure or high-temperature conditions is required. |

Limitations: When to Avoid Socket Weld Flanges

Despite their advantages in high-pressure containment, the design paradox of the required 1/16 inch expansion gap creates a critical internal crevice. This fundamental flaw leads to major application limitations:

- Corrosive Services: The internal crevice traps fluid, promoting localized crevice corrosion and solid buildup. Therefore, SW flanges are unsuitable for highly corrosive or erosive systems.

- Hygienic Applications: The crevice is extremely difficult to clean, creating a “dead zone” or “virtual leak”. Socket welding is unacceptable for sanitary systems, such as in the food or pharmaceutical industries, where flawless, crevice-free internal surfaces are mandatory.

- Maximum Strength: For applications demanding the absolute highest strength, fatigue resistance, and full volumetric NDT (like large-diameter critical pipelines), butt-welded connections (Weld Neck flanges) are preferred, as SW joints only resist about half the strength of butt-welds.

Your Partner in Steel Flange Excellence

Navigating the complexities of industrial piping components, from material specifications to critical welding procedures, requires a trusted partner.

At Nakoda Steel Industry, we specialize in providing high-quality, precision-engineered piping components, including a comprehensive range of socket weld flange solutions tailored to meet stringent industry standards. Whether your project demands robust carbon steel for a steam line or superior stainless steel for high-integrity small-bore systems, rely on our expertise to deliver products that ensure system safety, reliability, and longevity.