For any construction project across the United States, whether it is a high-rise in New York or an industrial warehouse in Texas, the structural integrity of the building relies heavily on one specific component: the steel beam. As the backbone of modern infrastructure, steel beams transfer loads from the roof and floors down to the foundation, ensuring stability and safety.

At Nakoda Steel Industry, we understand that navigating the terminology of structural steel can be complex. Choosing the wrong beam can lead to structural weaknesses, fabrication difficulties, and inflated costs. This guide breaks down the essential types of steel beams used in the US market, helping you make informed decisions for your next project.

The “Big Three”: W, S, and H Beams

While they may look similar to the untrained eye, the three primary categories of beams—W, S, and H—have distinct geometries and applications defined by ASTM standards.

1. W-Beams (Wide Flange)

The W-beam is the most commonly used structural steel shape in modern American construction. Often referred to generally as an “I-beam” because of its profile, the “W” stands for “Wide Flange.”

- The Design: The defining characteristic of a W-beam is that its flanges (the top and bottom horizontal plates) are parallel to each other. The inner and outer surfaces of the flanges are flat.

- The Advantage: The flat surfaces make fabrication much easier, specifically when bolting connections or welding stiffener plates. Because the web (the vertical section) contributes little to bending resistance, W-beams are designed with more mass in the flanges, making them highly economical and weight-efficient for long spans.

- Typical Use: These are the go-to beams for residential and commercial building frames, bridges, and mezzanines.

2. S-Beams (American Standard Beams)

Before the dominance of the W-beam, the S-beam was the industry standard. While less common in general framing today, they serve vital niche roles.

- The Design: S-beams feature a distinctive taper on the inner surface of their flanges. This slope is typically 16.67% (or a 2:12 slope). This results in a flange that is thicker at the web and thinner at the edges, giving it a curved appearance near the web connection.

- The Advantage: The thicker flange near the web provides excellent resistance to local flange bending and yielding under point loads.

- Typical Use: Because of the tapered flange, S-beams are the preferred choice for monorail hoists and crane rails. The wheels of under-hung cranes are often tapered to match the slope of the S-beam, allowing the hoist to self-level.

3. H-Beams (Bearing Piles)

While W-beams look like an “I,” H-beams look like a square “H.”

- The Design: In an H-beam, the width of the flanges is approximately equal to the depth of the beam. They also maintain a consistent thickness throughout the cross-section, meaning the web is often as thick as the flanges.

- The Advantage: This heavy, square geometry provides immense strength and stability. They are less flexible than W-beams but offer superior load-bearing capacity.

- Typical Use: H-beams are frequently used as bearing piles for deep foundations or as columns in skyscrapers where they must support massive vertical loads.

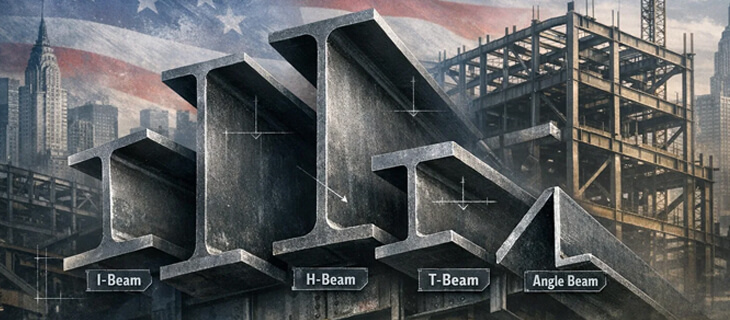

Beyond the I-Shape: Channels and Angles

Not all structural support comes in the form of an I-profile.

- Structural Channels (C-Beams): These beams have flanges on only one side of the web, creating a “C” shape. Also known as Parallel Flange Channels (PFC), they are lighter and often used for framing, wall supports, or rim joists where one flat side is needed for mounting cladding.

- L-Angle Beams: These are L-shaped sections with two legs connected at a 90-degree angle. While rarely used as primary load-bearing beams for long spans, they are essential for bracing, tension members, and connecting other structural elements.

System Integration: Connecting the Beams

A beam is only as good as its connection. In industrial settings, particularly in the oil, gas, and power generation sectors, beams often support complex piping systems. This brings us to the importance of fittings.

If your structural steel is supporting high-pressure piping, the integrity of your flanges is paramount. For example, systems exposed to extreme temperatures or corrosive environments often require alloy steel components rather than standard carbon steel. Finding reliable alloy steel flanges manufacturers in the us is critical for ensuring that the piping infrastructure supported by your beams meets the rigorous ASTM A182 standards for high-temperature service. Elements like chromium and molybdenum in these alloy flanges provide the necessary corrosion and heat resistance that standard carbon steel cannot match.

Choosing the Right Material

In the US, structural beams are regulated by ASTM International standards to ensure safety and consistency.

- Carbon Steel (A36, A992): The standard for most construction. A992 is the current standard for W-shapes, offering a higher yield strength (50 ksi) compared to older A36 steel.

- Alloy Steel: Used when environmental conditions (like high heat or corrosion) demand it. While more expensive, the longevity and reduced maintenance costs often justify the investment.

Why Choose Nakoda Steel Industry?

Selecting the right beam—whether it’s a W-beam for a building frame or an S-beam for a crane rail—requires balancing load capacity, span, and fabrication costs.

At Nakoda Steel Industry, we are committed to supplying high-quality structural steel products that meet the stringent demands of the American market. Whether you require standard carbon steel beams for construction or specialized alloy components for industrial applications, we ensure compliance with relevant ASTM and ASME standards.

Contact us today to discuss your project requirements and let us help you build a stronger tomorrow.